Contact Us

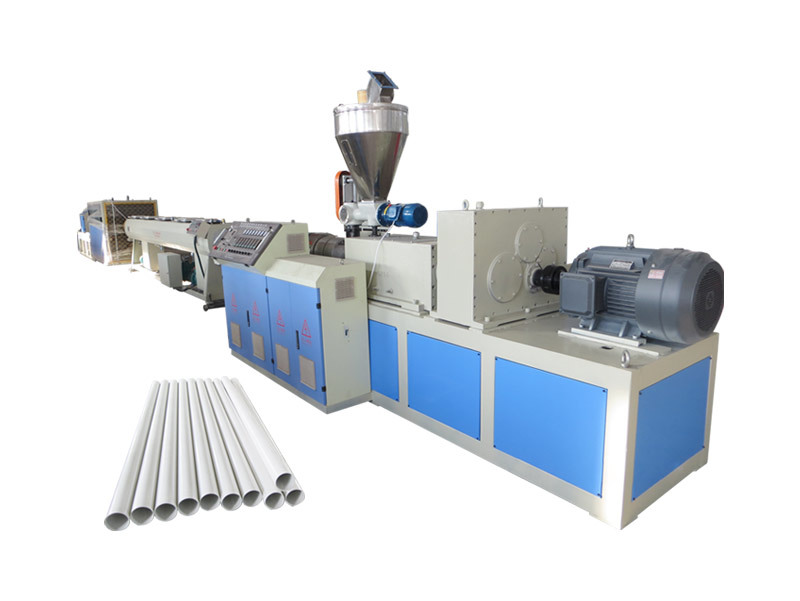

PVC Profile Production Line

- Commodity name: PVC Profile Production Line

- Product Description

-

The YF series PVC profile production line is mainly used for extrusion of PVC door and window profiles, wide width door panels, window sills, and porous conduit (four hole, six hole, seven hole, nine hole, etc.). This production line can select parallel (conical) twin-screw extruders of different specifications based on different profiles and molds, and is equipped with corresponding auxiliary equipment such as vacuum shaping table, traction machine, cutting machine, and flipping platform.

The extrusion capacity of the host can be selected between 60 kilograms and 700 kilograms per hour. The traction machine adopts our company's unique lifting technology, which operates smoothly, has good reliability, and has a large traction force. Vacuum shaping adopts a special enlarged eddy current cooling system, which is convenient for cooling and shaping to meet the needs of high-speed extrusion. The movement speed of the cutting machine is synchronized with the traction speed, and all actions are controlled by an imported PLC computer. The design is reasonable, the operation is stable, and it can automatically cut at a fixed length. It is also equipped with a dust recovery device. According to different molds, the shaping table can be selected in sizes of 4 meters, 6 meters, 8 meters, 11 meters, etc. Equipped with a parallel twin screw extruder, particularly suitable for high-speed extrusion of profiles.Production Process:

● Ingredients and Mixing: Firstly, according to the formula requirements, mix PVC resin with various additives (such as stabilizers, impact inhibitors, processing aids, lubricants, colorants, fillers, etc.) in a certain proportion. This step requires precise weighing and uniform mixing to ensure that the produced PVC profiles have good physical and chemical properties.

● Extrusion molding: The mixed molded plastic is fed into the extruder, and through heating and screw propulsion, the plastic is melted and extruded into shape. The selection of extruder varies depending on the cross-section of the profile and the type of mold, and can be a conical twin-screw extruder or a parallel twin-screw extruder.

● Shaping and cooling: The extruded profiles are shaped and initially cooled through a shaping table and vacuum cooling shaping mold to ensure stable shape and size of the profiles.

● Traction and cutting: The shaped profile is stretched by a traction machine and cut by a cutting machine according to the required length.

Post processing: The cut profile may require further processing, such as surface treatment, welding, assembly, etc., to meet the requirements of the final application.

Features:

● High degree of automation: Modern PVC profile production lines usually have the characteristics of high automation, which can continuously and stably produce, reduce manual intervention, and improve production efficiency.

● Diversified products: The production line can produce various PVC profiles and molds based on different profiles, such as door and window profiles, window sills, etc., to meet different market demands.

● Mature technology: The PVC profile production line has mature technology, which can ensure the stability and reliability of product quality, while also having a certain degree of flexibility, and can be appropriately modified and adjusted according to customer needs.

● Environmental protection and energy conservation: In the production process, optimizing processes and equipment can reduce energy consumption and waste, achieving environmentally friendly production.

● Quality control: The production line is equipped with advanced quality control equipment and systems to ensure that each batch of products can meet the predetermined quality standards.

● The PVC profile production line is a production system that integrates high efficiency, high quality, and high automation, which can meet the demand for PVC profiles in the modern construction industry.

Main Technical Parameters Model YF180

YF240

YF300

YF600

YF900

YF1200

Maximum Board Width (mm) 180

240

300

600

900

1200

Traction Height (mm) 150

150

150

150

150

150

Traction Force (KN) 2

2

2

30

40

50

Traction Speed (m/s) 0-5

0-5

0-5

0-3

0-2.5

0-2.5

Total Power of Auxiliary Equipment (kW) 35

35

30

30

40

45

Auxiliary Cooling Water Capacity (m³/h) 6

6

6

9

12

15

Compressed Air Pressure (Mpa) 0.6

0.6

0.6

0.6

0.6

0.6

Keywords:

Shipping Photos

Export to Russia

Export to Rwanda

Export to Cameroon

Export to Vietnam

Factory Workshop

FAQ

01

Are we manufacture or trade company?

02

What kind machines we produce?

03

What kind payment we accept?

04

How long we need to produce the machines?

05

Will the machine be delivered on time ?

06

How about the machine quality?

07

How about the price?

08

How long is your machine’s guarantee time?

09

What can you provide for after sale service?