Contact Us

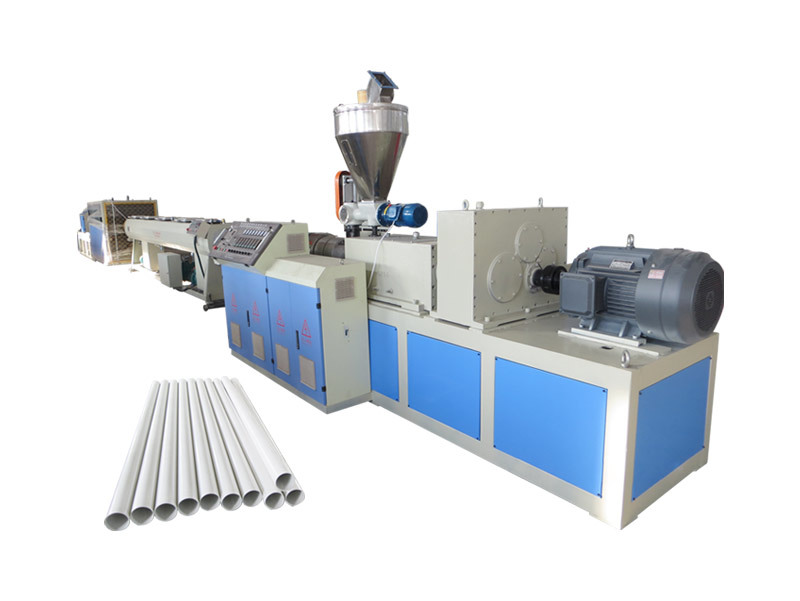

PP/PE/ABS Thick Plate Production Line

- Commodity name: PP/PE/ABS Thick Plate Production Line

- Product Description

-

Impact resistance, corrosion resistance, high heat resistance, non-toxic and odorless, smooth and beautiful surface, low density and light weight, easy processing, stable size, rigidity, good heat resistance, no toxic gas generated during welding.

Application scope: PCB and metal surface treatment tank, PCB wet treatment equipment, factory exhaust emission system equipment, wastewater and other environmental protection system equipment, semiconductor industry related equipment, can also be filled, flame-retardant, modified, surface can be embossed, frosted.

Processing range: thickness 1-30mm, width within 3000mm.Parameter PP Thick Plate Production Line PE Thick Plate Production Line ABS Thick Plate Production Line Application Area Chemical industry, food industry, anti-corrosion industry, purification industry, and environmental protection equipment production industry Chemical, power and other industries Industries such as home appliances, electronics, packaging, and medical devices Board Type PP Board HDPE Board ABS Board Board Width Up to 2000mm Maximum 1500mm Plate Thickness 3mm-50mm 3mm-45mm 1mm-30mm Extrusion Yield 300kg/h - 400kg/h 650kg/h

Keywords:

Shipping Photos

Export to Russia

Export to Rwanda

Export to Cameroon

Export to Vietnam

Factory Workshop

FAQ

01

Are we manufacture or trade company?

02

What kind machines we produce?

03

What kind payment we accept?

04

How long we need to produce the machines?

05

Will the machine be delivered on time ?

06

How about the machine quality?

07

How about the price?

08

How long is your machine’s guarantee time?

09

What can you provide for after sale service?