Contact Us

PVC Wood Plastic Building Formwork Production Line

- Commodity name: PVC Wood Plastic Building Formwork Production Line

- Product Description

-

Compared with traditional templates, PVC wood plastic building templates have the following characteristics:

● Good water resistance. Even if completely immersed in water for several days, it will not deform due to moisture. It will not rot or rust.

● Not compatible with cement, sticky, easy to demould after construction, and will not deform due to cement adhesion.

● High construction efficiency and good quality. The surface of the building constructed with it is smooth and flat, without the need for secondary decoration.

● Saves processes and improves construction efficiency. At the same time, it is also possible to pre treat the surface of the template during processing to obtain the desired wall pattern.

● Lightweight and convenient for construction.

● Long lifespan and frequent reuse. The ultimately damaged plastic template can still be crushed again and reprocessed into a new template, saving resources and meeting the requirements of "green industry".

● Good insulation is beneficial for shortening the construction period.

● Various treatments can be carried out by adding wood, and welding can also be carried out, so secondary processing can be flexibly carried out on the construction site.

Application of PVC wood plastic templates:

It can be widely used in industries, agriculture, national defense, construction, household appliances, and daily necessities. It can be used to make various products, such as industrial pallets, warehouse mats, carriage floors, warehouse shelves, wooden fences, beach chairs, floors, etc.

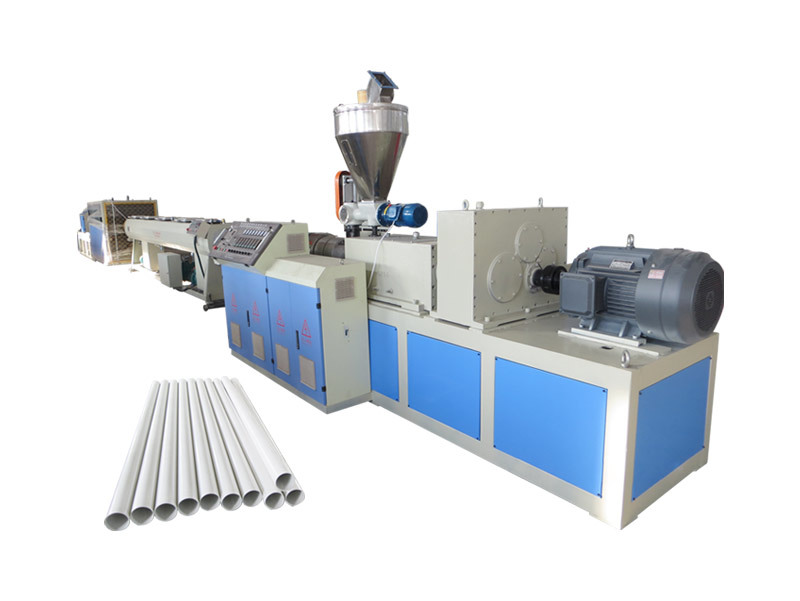

Parameter Describe Notes Production Raw Materials Mainly composed of PVC waste plastics, wood powder, calcium carbonate, and other fillers These raw materials are used to produce building templates through extrusion technology Production Equipment Including twin-screw extruder, sheet metal mold, shaping table (three rollers), and auxiliary machine composition Conical twin screw extruder used to improve yield and extrusion stability Product Size The common width is 915mm to 1220mm, and the thickness range is 2mm to 18mm Adjust according to the specific production line capacity and market demand Yield 350kg/h - 500kg/h High yield equipment can meet the needs of large-scale production Product Features Durability, environmental friendliness, practicality, functionality, safety, and economy Specific features include anti-aging, non deformation, non absorbent, reusable, etc Application Area Widely used in various fields such as construction, decoration, advertising, transportation, chemical anti-corrosion, etc PVC wood plastic building formwork is widely used in multiple industries due to its versatility Environmental Effect The production process is non-toxic and harmless, meeting the requirements of green industry The product can be recycled and reused after use, reducing environmental pollution

Keywords:

Shipping Photos

Export to Russia

Export to Rwanda

Export to Cameroon

Export to Vietnam

Factory Workshop

FAQ

01

Are we manufacture or trade company?

02

What kind machines we produce?

03

What kind payment we accept?

04

How long we need to produce the machines?

05

Will the machine be delivered on time ?

06

How about the machine quality?

07

How about the price?

08

How long is your machine’s guarantee time?

09

What can you provide for after sale service?