Contact Us

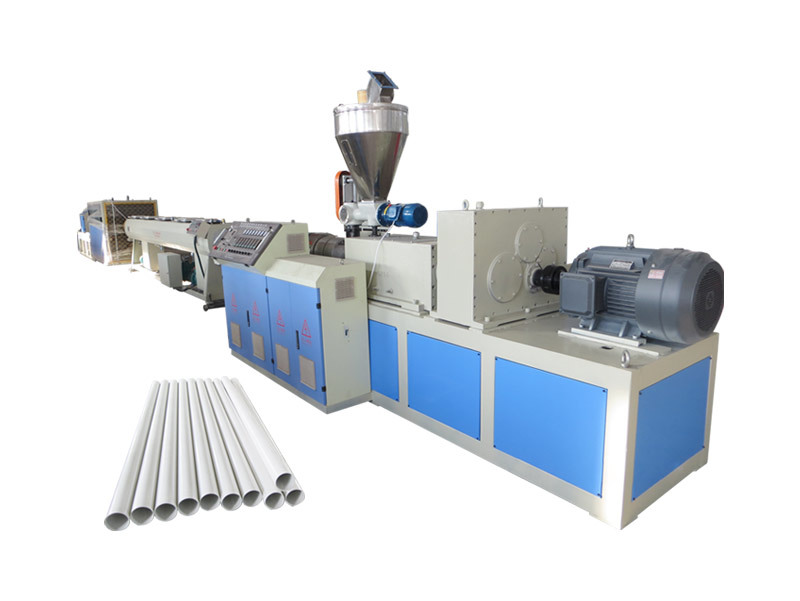

Plastic Building Formwork Production Line

- Commodity name: Plastic Building Formwork Production Line

- Product Description

-

The unit consists of a single screw plastic extruder, an automatic vacuum feeding machine, a dehumidification and drying hopper, a sheet metal head, a three roller calender, a heating and leveling device, a row roller cooling device, an edge cutting device, a traction machine, a cutting machine, a row roller conveyor, etc. The unit has a compact structure and superior performance. The screw and barrel have been optimized and processed using high-performance alloy steel 38CrMoAiA, making the entire machine have advantages such as uniform plasticization, stable extrusion, high output, and long service life. The main engine screw adopts a cast aluminum heater for heating, air cooling, and precise electronic control instruments for temperature control. The precise shaping and pressing device ensures excellent shaping of the board through its excellent adjustment function. The cutting part adopts a fixed length cutting device to ensure accurate board length.

Compared with traditional templates, it has the following characteristics:

● Good water resistance. Even if completely immersed in water for several days, it will not deform due to moisture. It will not rot or rust.

● It is not compatible with cement and sticky, making it easy to demould after construction and will not deform due to cement adhesion.

● High construction efficiency and good quality. The surface of the building constructed with it is smooth and flat, without the need for secondary decoration.

● It saves processes and improves construction efficiency. At the same time, it is also possible to pre treat the surface of the template during processing to obtain the desired wall pattern.

● Lightweight and convenient for construction.

● Long lifespan and frequent reuse. The ultimately damaged plastic template can still be crushed again and reprocessed into a new template, saving resources and meeting the requirements of "green industry".

● Good insulation is beneficial for shortening the construction period.

● Various treatments can be carried out by adding wood, and welding can also be carried out, so secondary processing can be flexibly carried out on the construction site.

Parameter Describe Notes Extruder Type Single or twin screw extruders Single screw extruder is suitable for simple profile production, while double screw extruder is suitable for complex or co extruded products Product Structure Single layer, three-layer co extruded structure The three-layer co extrusion structure provides better performance and stability Product Width 915mm - 1830mm Determine based on market demand and application scenarios Product Thickness 12mm, 15mm, 18mm, 21mm The thickness is adjusted according to the usage requirements of the building formwork Yield 350kg/h - 450kg/h Production capacity depends on the scale and design of the production line Product Features Corrosion resistance, good water resistance, light weight, high usage efficiency, low cost, environmental protection, etc These characteristics make plastic building templates widely used in the construction industry Application Area Residential buildings, office buildings, shopping malls, stations, water conservancy, bridges, tunnels, etc Plastic building templates can be used in various construction projects to improve construction efficiency and quality Reuse Frequency 40-100 Times PP hollow plastic building formwork has a high turnover rate and reduces costs Comprehensive Cost Savings Save more than 30% compared to traditional wooden templates The comprehensive use cost of plastic templates is lower than that of traditional templates, which has cost advantages

Keywords:

Shipping Photos

Export to Russia

Export to Rwanda

Export to Cameroon

Export to Vietnam

Factory Workshop

FAQ

01

Are we manufacture or trade company?

02

What kind machines we produce?

03

What kind payment we accept?

04

How long we need to produce the machines?

05

Will the machine be delivered on time ?

06

How about the machine quality?

07

How about the price?

08

How long is your machine’s guarantee time?

09

What can you provide for after sale service?