Contact Us

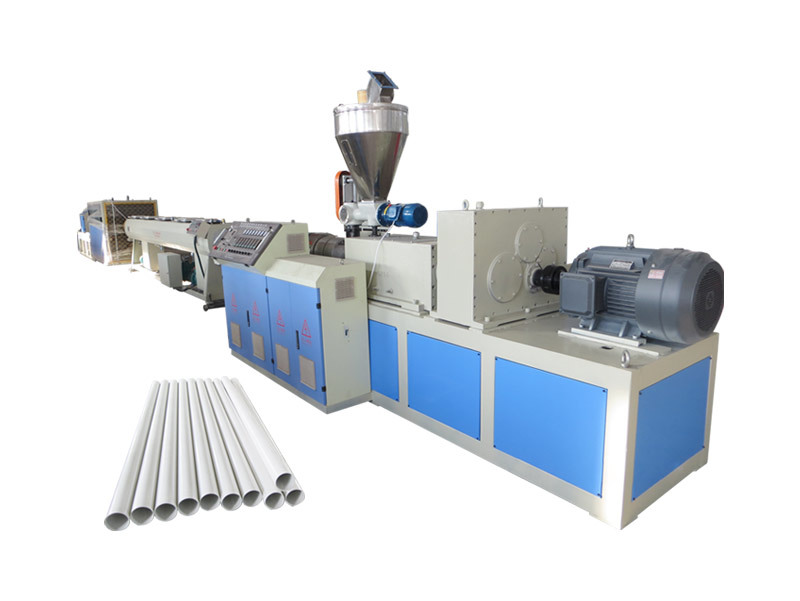

PVC Wood Plastic, Decorative Lines, PVC Buckle Production Line

- Commodity name: PVC Wood Plastic, Decorative Lines, PVC Buckle Production Line

- Product Description

-

Production Process:

● Raw material preparation: The raw materials for PVC wood plastic production line mainly include PVC resin and wood powder. These raw materials need to undergo pre-treatment, such as drying and crushing, to meet the requirements of subsequent processing.

● Mixing: Mix PVC resin, wood powder, and other additives (such as stabilizers, lubricants, etc.) in a specific proportion. This step has a significant impact on the performance of the final product.

● Extrusion molding: The mixed raw materials are fed into the extruder, and the plastic is melted and extruded through heating and screw propulsion. The selection and configuration of extruders are crucial to the quality and production efficiency of products.

● Cooling and shaping: The extruded profiles are cooled and shaped through a cooling and shaping device to ensure their stability in shape and size.

● Cutting and post-treatment: The cooled wood plastic profiles are cut as needed and subjected to subsequent surface treatments such as polishing and painting to improve the aesthetics and durability of the product.Features:

● Environmental protection and energy conservation: PVC wood plastic materials combine the advantages of wood and plastic, and have good environmental performance and renewable resources.

● Strong weather resistance: PVC wood plastic material has excellent weather resistance and anti-aging performance, suitable for long-term outdoor use.

● Diversified applications: PVC wood plastic materials can be widely used in various fields such as architecture, furniture, and landscaping, with broad market prospects.

The production process and characteristics of decorative line production line:

● Drawing review and mold making: Firstly, the computer draftsman reviews the production drawings of the decorative lines to ensure understanding of the design intent, and performs CAD drawing.

● Template making: Based on the drawing results, create a template and polish the surface of the template to ensure that the geometric dimensions and surface smoothness meet the requirements.

● EPS line cutting: Use specialized cutting equipment to cut EPS blocks, ensuring the accuracy of cutting dimensions.

● Review and numbering: Verify the size of the cut EPS lines and label them with numbers and batches to ensure traceability of the production process.

Features:

● High precision: The decorative line production line can produce decorative lines with high precision and consistent size, meeting the design requirements of architectural designers.

● High production efficiency: Through optimized process flow and automated equipment, the production efficiency and product quality of EPS decorative lines have been improved.

The production process and characteristics of PVC buckle plate production line:

● Formula design: Select a formula suitable for the production of PVC buckle plates, including PVC resin, fillers (such as calcium powder), stabilizers, lubricants, etc.

● Mixing: Mix the ingredients in the formula to ensure uniform distribution.

● Extrusion molding: The mixed raw materials are extruded through a twin-screw extruder to form PVC buckle plates.

● Cooling and cutting: After the extruded PVC buckle is cooled and shaped, it is cut according to the specifications.

● Packaging: Cut PVC buckle plates are packaged for easy transportation and sales.

Features:

● Strong adaptability: The PVC buckle plate equipment production line can adapt to various formulas and has high production flexibility.

● Fine appearance: The production line can produce PVC buckle plates with fine appearance and uniform plasticization, meeting the market's demand for high-quality products.

● Cost effectiveness: By optimizing the formula and production process, production costs have been reduced and the market competitiveness of the product has been improved.

In summary, PVC wood plastic, decorative lines, and PVC buckle production lines each have unique production processes and characteristics, and they play an important role in the fields of building decoration and material manufacturing. Through continuous technological innovation and process optimization, these production lines can provide high-quality and high-performance PVC products to meet the diverse needs of the market.

Main Technical Parameters Type SY Model 120 Small Profile SY Model 240 Ceneral-Purpose SY Model 240 Quasi-High Speed SY Model 240A High Speed Max Vacuum -0.096 -0.096 -0.096 -0.096 Number of Vacuum Joints 30 30 40 40 Effective Supporting Film Length of the Shaping Table 3000 4000 4000/5000 6000/8000 Max Drawing Force 20 30 40 40 Max Drawing Speed 8 3 5 5 Crawler Width 200 240 240 240 Water Consumption 2.5 4 5 6 Gas Consumption 8 10 12 15 Total Power 24.3 27 33.5 34.7 Size 15100*860*1400 13500*1045*1760 16385*1465*2127

17135*1465*2127

18750*1465*2130

19410*1645*2130

Keywords:

Shipping Photos

Export to Russia

Export to Rwanda

Export to Cameroon

Export to Vietnam

Factory Workshop

FAQ

01

Are we manufacture or trade company?

02

What kind machines we produce?

03

What kind payment we accept?

04

How long we need to produce the machines?

05

Will the machine be delivered on time ?

06

How about the machine quality?

07

How about the price?

08

How long is your machine’s guarantee time?

09

What can you provide for after sale service?