Contact Us

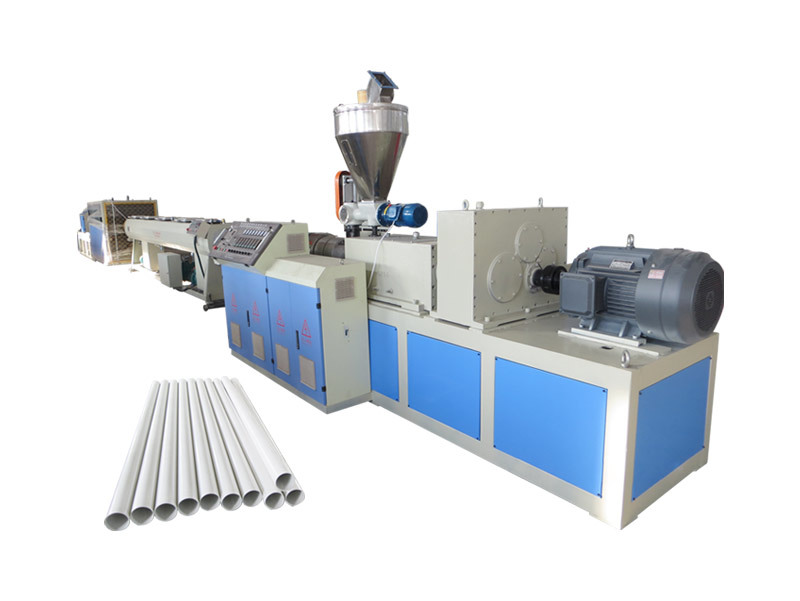

Hollow Winding Pipe Machine

- Commodity name: Hollow Winding Pipe Machine

- Product Description

-

The PE large-diameter winding pipe production line developed by Qingdao Jinsu Machinery, which absorbs new technologies from both domestic and foreign sources, can produce high-quality drainage pipes with diameters ranging from 200 to 3000. This pipe is increasingly becoming the mainstream product of urban drainage pipes and will gradually replace steel pipes, cement pipes, and other plastic pipes.

The PE large-diameter winding pipe production line consists of irregular pipe extruders, fusion extruders, winding forming machines, cutting machines, and related auxiliary machines. It has the advantages of large production volume, high production efficiency, stable operation, high pipe ring stiffness, small unit weight, excellent creep resistance, convenient connection, and economical construction.

The extruders all adopt specially designed high-efficiency single screw extruders, with unique screw and barrel structures, high output, low energy consumption, excellent plasticization, and reasonable mold structure. The dual machine joint feeding rotary molding is ingenious in concept and unique in design.

Advanced PLC computer control system can be used, which is easy to operate and has stable and reliable actions.

Adopting a two-stage pressure reducing screw with special mixing and plasticizing elements, high torque, and high temperature control accuracy.

Adopting a composite head, dual machine joint feeding, spiral rotation molding, and efficient composite technology to ensure the high quality of the product.

Keywords:

Shipping Photos

Export to Russia

Export to Rwanda

Export to Cameroon

Export to Vietnam

Factory Workshop

FAQ

01

Are we manufacture or trade company?

02

What kind machines we produce?

03

What kind payment we accept?

04

How long we need to produce the machines?

05

Will the machine be delivered on time ?

06

How about the machine quality?

07

How about the price?

08

How long is your machine’s guarantee time?

09

What can you provide for after sale service?