Contact Us

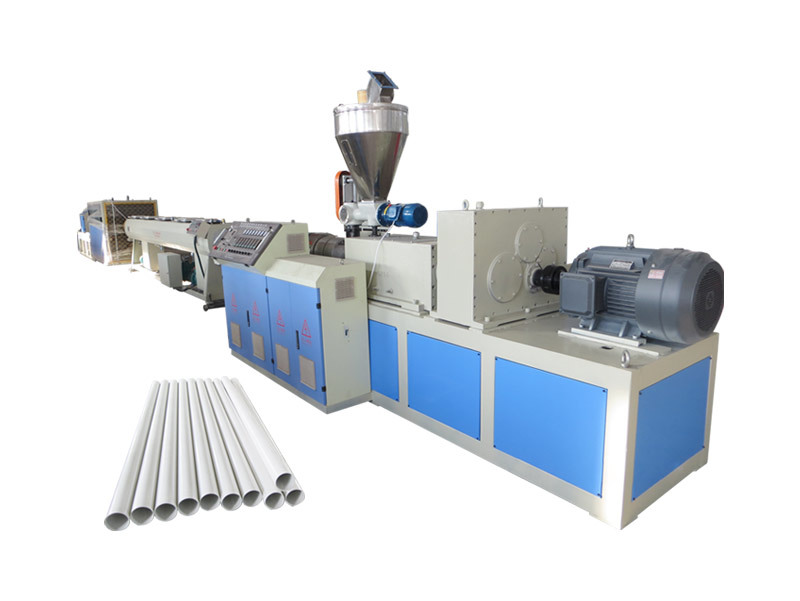

Beverage Straw Machine

- Commodity name: Beverage Straw Machine

- Product Description

-

● High degree of automation: Modern beverage straw machines usually have automated processes such as raw material transportation, extrusion molding, cooling, cutting, and packaging, reducing manual operations and improving production efficiency.

● Diversified cutting angles: The machine can adjust the cutting angles according to needs, such as 90 °/90 °, 90 °/45 °, etc., to adapt to the production of straws of different lengths and shapes.

● Multi color co extrusion function: Some high-end models support single color extrusion and dual color co extrusion, providing a wider range of product choices and higher product added value.

● Simple structure and easy operation: The machine is designed reasonably, easy to operate and maintain, ensuring the stability and efficiency of the production process.

● Corrosion resistant and wear-resistant materials: Key components such as the barrel and screw are made of corrosion-resistant and wear-resistant materials to extend the service life of the equipment.

Main Technical Parameters Category Parameter Describe Extruder Screw Diameter Depending on the production line model Length to Diameter Ratio Usually between 20:1 and 30:1 Cutting Angle Adjustable, such as 90 °/90 °, 90 ° /45 °, etc Color Extrusion Supports single color extrusion and dual color co extrusion Automation Level High, including raw material transportation, forming, cutting and other links Corrosion Resistant Materials Barrel, Screw Materials that are resistant to corrosion and wear Production Speed Depending on equipment model and production conditions Straw Diameter Customized according to needs Straw Length Adjustable to meet different length requirements Packaging Method Supports automatic counting and secondary packaging

Keywords:

Shipping Photos

Export to Russia

Export to Rwanda

Export to Cameroon

Export to Vietnam

Factory Workshop

FAQ

01

Are we manufacture or trade company?

02

What kind machines we produce?

03

What kind payment we accept?

04

How long we need to produce the machines?

05

Will the machine be delivered on time ?

06

How about the machine quality?

07

How about the price?

08

How long is your machine’s guarantee time?

09

What can you provide for after sale service?