Contact Us

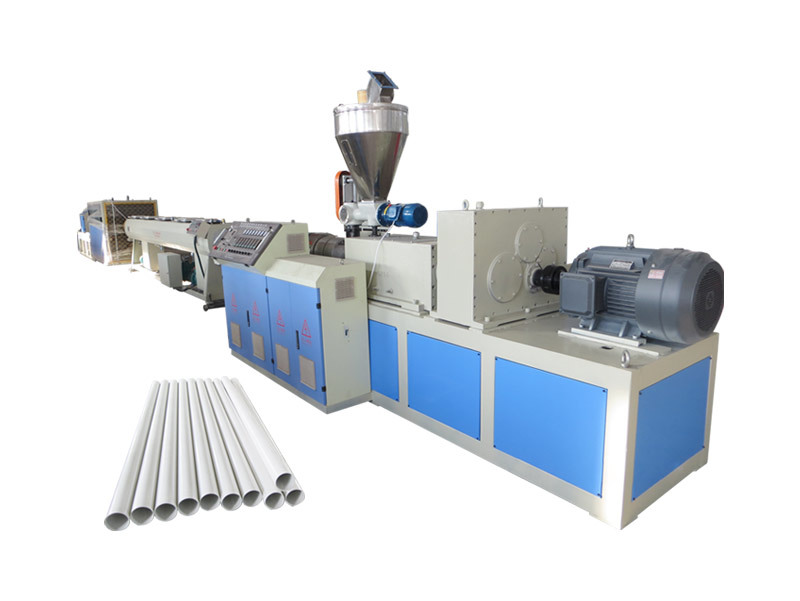

Porous Plum Blossom Pipe Machine

- Commodity name: Porous Plum Blossom Pipe Machine

- Product Description

-

● High automation production: Production lines usually have automated processes such as raw material transportation, extrusion molding, cooling, cutting, and stacking, reducing manual operations and improving production efficiency.

● Unique mold design: Using a special plum blossom shaped mold, porous pipes are formed in one go, improving production efficiency and consistency of the pipes.

● Diversified hole selection: capable of producing plum blossom tubes ranging from three to nine holes to meet different threading needs.

● Good physical properties: The produced plum blossom tube has good stiffness and uniform force distribution, low friction coefficient on the inner wall, and is easy to thread cables.

● Temperature resistance: Suitable for a wide temperature range and can be used in environments ranging from -40 ℃ to+80 ℃, suitable for various climatic conditions.

● Simple connection method: The joint adopts a sleeve joint structure, which can complete the connection between pipes without special tools, making it easy for construction and maintenance.

● Strong corrosion resistance: The PVC or HDPE materials used have excellent corrosion resistance and are suitable for various soil environments.

Main Technical Parameters Category Parameter Describe Raw Material PVC Particles or HDPE Particles Number of Holes Ranging From Three to Nine Holes Production Speed Depending on equipment model and production conditions Applicable Temperature Range -40 ℃ to+80 ℃ Connection Method Socket structure for easy construction and maintenance Physical Property Stiffness Good, evenly stressed Inner Wall Friction Coefficient Small, easy to thread cables Corrosion Resistance Strong, suitable for various soil environments Construction Simplicity Structural design makes construction operations simple and feasible

Keywords:

Shipping Photos

Export to Russia

Export to Rwanda

Export to Cameroon

Export to Vietnam

Factory Workshop

FAQ

01

Are we manufacture or trade company?

02

What kind machines we produce?

03

What kind payment we accept?

04

How long we need to produce the machines?

05

Will the machine be delivered on time ?

06

How about the machine quality?

07

How about the price?

08

How long is your machine’s guarantee time?

09

What can you provide for after sale service?