Contact Us

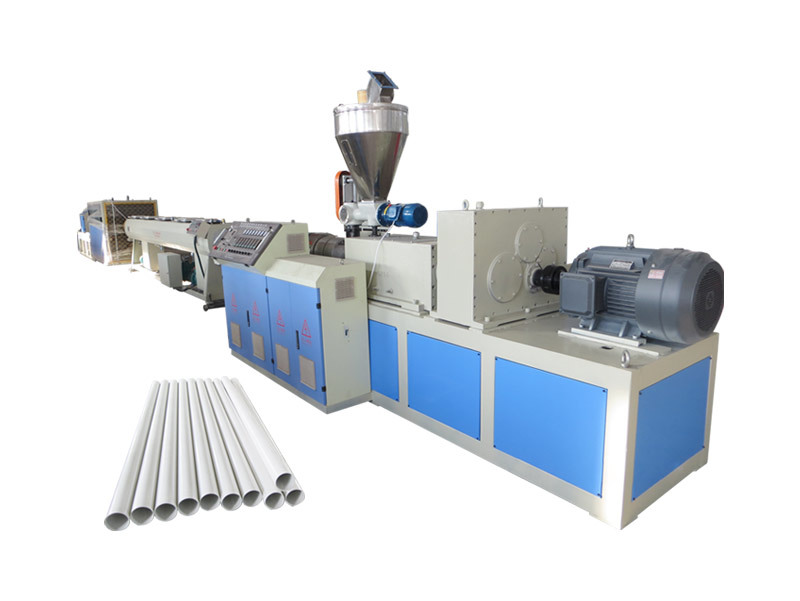

PPR Pipe Machine

- Commodity name: PPR Pipe Machine

- Product Description

-

● High degree of automation: PPR pipe production lines usually have automated processes such as raw material transportation, extrusion molding, sizing cooling, cutting, and stacking, reducing manual operations and improving production efficiency.

● Good plasticizing ability: Adopting efficient screw design to ensure good plasticizing effect of PPR material, producing pipes with stable quality.

● Multifunctionality: By changing molds and adjusting production line configurations, PPR pipes with different diameters and wall thicknesses can be produced to meet diverse production needs.

● Energy saving and environmental protection: PPR pipes have good insulation performance and low thermal conductivity, which helps to save energy and reduce emissions.

● Reliable connection: PPR pipes are connected by hot melt or electric fusion, with high strength at the connection point, ensuring the sealing and durability of the pipeline system.

● Economy: The production cost of PPR pipes is relatively low, and due to their corrosion resistance and long service life, the overall economic benefits are significant.

Main Technical Parameters Pipe Range (mm) 20-60 Main Engine 75/33 Mould Double Production Line Speed (m/min) 2-20 Total Power (kW) 125

Keywords:

Shipping Photos

Export to Russia

Export to Rwanda

Export to Cameroon

Export to Vietnam

Factory Workshop

FAQ

01

Are we manufacture or trade company?

02

What kind machines we produce?

03

What kind payment we accept?

04

How long we need to produce the machines?

05

Will the machine be delivered on time ?

06

How about the machine quality?

07

How about the price?

08

How long is your machine’s guarantee time?

09

What can you provide for after sale service?