Contact Us

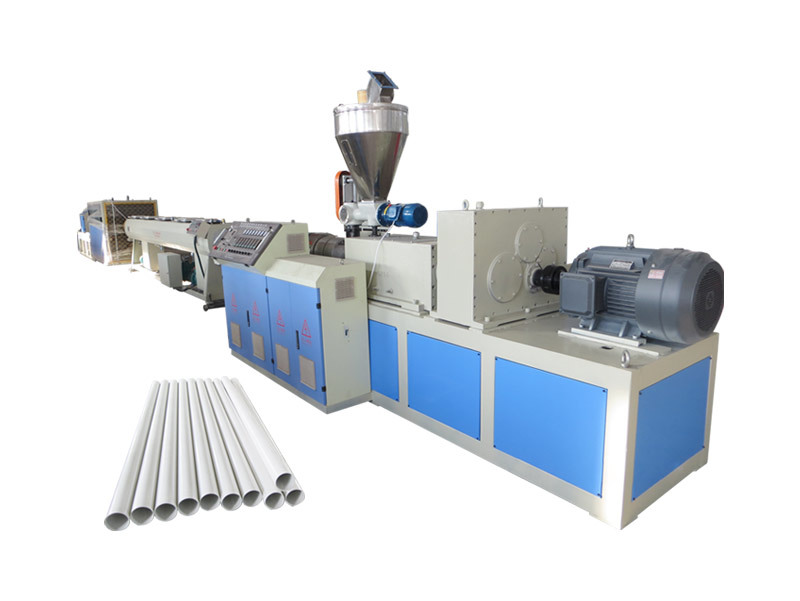

PERT Underfloor Heating Pipe Machine

- Commodity name: PERT Underfloor Heating Pipe Machine

- Product Description

-

● Efficient extrusion capability: PERT underfloor heating pipe machines are usually equipped with efficient single screw extruders to ensure efficient production processes and excellent pipe quality.

● Heat resistance: PERT underfloor heating pipes have good heat resistance and are suitable for high-temperature hot water systems, with long-term operating temperatures ranging from 60 ℃ to 80 ℃.

● Pressure resistance: PERT underfloor heating pipes have high pressure resistance and are suitable for high pressure heating systems.

● Good flexibility: The PERT underfloor heating pipe material is flexible, easy to install and layout, and suitable for use in narrow spaces or curved paths.

● Corrosion resistance: PERT underfloor heating pipes have good corrosion resistance to chemicals such as acid and alkali, and are suitable for various chemical transportation environments.

● Environmentally friendly and non-toxic: PERT floor heating pipe material is non-toxic and odorless, meets hygiene standards, and is suitable for household floor heating systems.

● Hot melt connection: PERT underfloor heating pipes can be connected through hot melt connection technology to ensure sealing and reliability of the connection.

Main Technical Parameters Model

Production Scope

Yield

Installed Power

SJ65

20--32

150KG

60KW

SJ75

20--32

190KG

75KW

Keywords:

Shipping Photos

Export to Russia

Export to Rwanda

Export to Cameroon

Export to Vietnam

Factory Workshop

FAQ

01

Are we manufacture or trade company?

02

What kind machines we produce?

03

What kind payment we accept?

04

How long we need to produce the machines?

05

Will the machine be delivered on time ?

06

How about the machine quality?

07

How about the price?

08

How long is your machine’s guarantee time?

09

What can you provide for after sale service?