Contact Us

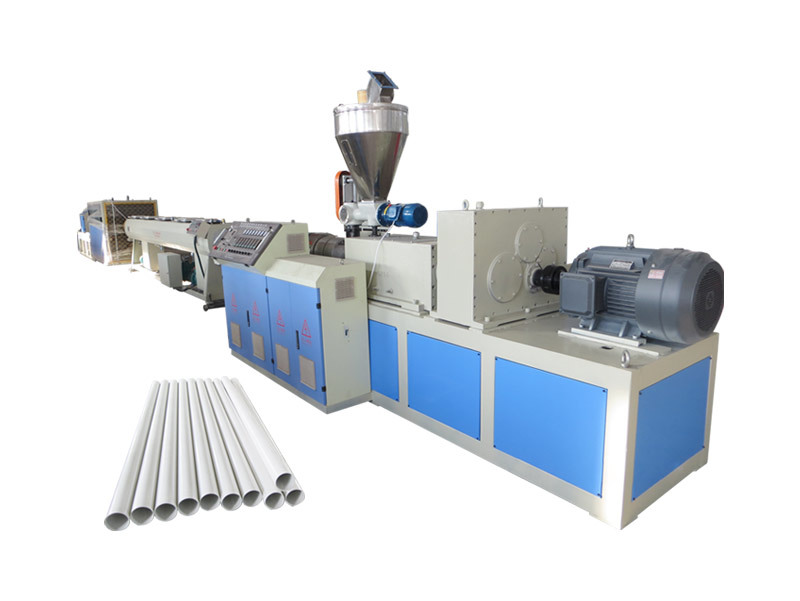

Single Wall Corrugated Pipe Machine

- Commodity name: Single Wall Corrugated Pipe Machine

- Product Description

-

● Multi material applicability: The production line is equipped with different extruders, which can produce single wall corrugated pipes of different materials such as PE, PP, PVC, etc.

● High production efficiency: The molding speed is fast, up to 25m/min, ensuring an efficient production process.

● Cost and time savings: The single wall corrugated pipe machine can produce pipes of different diameters by changing the mold, reducing the time and cost of mold replacement.

● Widely used products: Single wall corrugated pipes have the characteristics of high temperature resistance, corrosion resistance, wear resistance, high strength, and good flexibility. They are widely used in fields such as automotive wires, electric conduit, machine tool circuits, lamp wire protection pipes, air conditioning pipes, washing machines, etc.

● Energy saving and environmental protection: By using an electromagnetic heater, it can save 40% to 60% of electricity.

● Electrical component quality assurance: All electrical components (circuit breakers/relays/inverters) are well-known brands such as SIEMENS/SCHNEIDER/OMRON, ensuring the stability and durability of the equipment.

● PLC control: Adopting a PLC control system, the operation is simple and improves the automation level of production.

● High molding quality: The molding machine has multiple pairs of molding blocks, ensuring smooth inner and outer surfaces of the pipe and uniform ripple shapes.

Main Technical Parameters Extruder Model SJ-30/25 SJ-45/33 SJ-65/30 SJ-65/33 Main Motor Power (KW) 5.5 11-18.5 30-45 55 Number of Modules 52 45-72 50-72 55 Pipe Diameter (mm) 4-17 10-35 40-110 75-200 Speed (m/min) 5-15 15-20 10-20 3-15 Yield (kg/h) 15 60-100 100-150 100-180

Keywords:

Shipping Photos

Export to Russia

Export to Rwanda

Export to Cameroon

Export to Vietnam

Factory Workshop

FAQ

01

Are we manufacture or trade company?

02

What kind machines we produce?

03

What kind payment we accept?

04

How long we need to produce the machines?

05

Will the machine be delivered on time ?

06

How about the machine quality?

07

How about the price?

08

How long is your machine’s guarantee time?

09

What can you provide for after sale service?