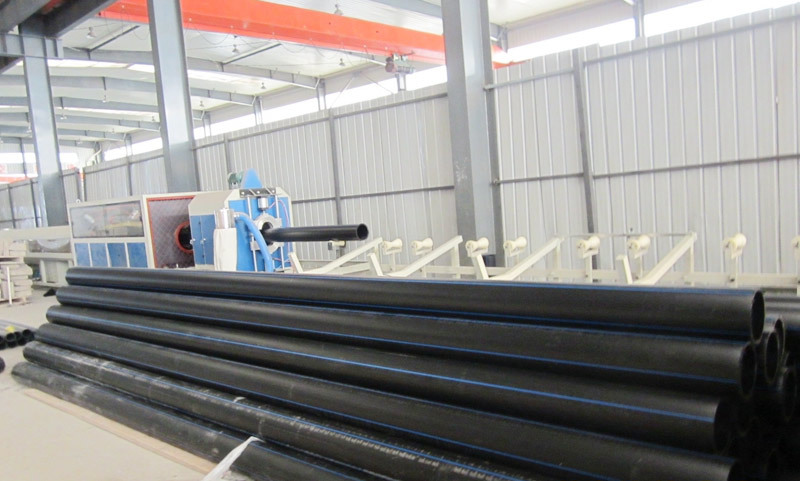

Advantages and application areas of PE pipe production line manufacturing

Release Time:

Jun 06,2024

The PE pipe production line pipeline system has a development history of nearly 70 years, as high modulus, high strength, and low price have always been the most widely used plastic pipeline system in the world.

The PE pipe production line pipeline system has a development history of nearly 70 years, as high modulus, high strength, and low price have always been the most widely used plastic pipeline system in the world. However, for a period of time, the performance level of PVC pipeline systems did not improve significantly, and the growth rate slowed down in some countries and application fields.

Although China's PVC pipeline system has formed a huge scale with an annual output of over 1 million tons, it has always remained within the traditional scope. Many enterprises are not familiar with the trends and progress of international pipeline technology innovation, because slow technological progress has hindered further promotion and application. Here, we will introduce some characteristics of PE pipes to you

1. Non toxic and hygienic: The material of the pipe is non-toxic and belongs to the category of green building materials, which do not corrode or scale.

2. Corrosion resistance: Polyethylene is an inert material that, except for a few strong oxidants, can withstand the erosion of various chemical media, has no electrochemical corrosion, and does not require an anti-corrosion layer.

3. Convenient connection: Polyethylene pipes mainly use hot melt and electric melt connections to integrate the pipeline system. It has good resistance to water hammer pressure, and the fusion joint integrated with the pipe and polyethylene pipe have effective resistance to underground movement and end loads, greatly improving the safety and reliability of water supply and improving water utilization efficiency.

4. Low flow resistance: The absolute roughness coefficient of the inner wall of the polyethylene water supply pipe does not exceed 0.01, which can effectively reduce water supply consumption.

5. High toughness: Polyethylene water supply pipes are a type of high toughness pipe material with a fracture elongation rate generally exceeding 500%. They have a strong adaptability to uneven settlement of the pipe foundation and are a type of pipeline with excellent seismic performance.

6. Excellent flexibility: The flexibility of polyethylene pipes allows polyethylene water supply pipes to be coiled and supplied in longer lengths, avoiding a large number of joints and fittings, and increasing the economic value of the material for pipelines.

7. Long service life: The safe service life of polyethylene pressure pipelines is more than 50 years.

PE pipe application field:

1. Urban water supply system

2. Transportation systems in the food and chemical industries

3. Mineral sand and mud conveying system

4. Landscape greening pipeline network

5. Replace cement pipes, cast iron pipes, and steel pipes

Key words:

Related News